Dear Golem,

For those who would like to add a step motor to a existing box joint jig (finger joint machine) or those who have little experience with step motors, we made a small video:

On youtube, one can find very nice video’s how to create a box joint sawing jig. Most of them have a spindle so it might be an idea to attach a step motor to this spindle and use the jointmaster total time saver solution or jointmaster 0.5 euro solution. These kits includes software + hardware except for step motor, power supply and step motor driver.

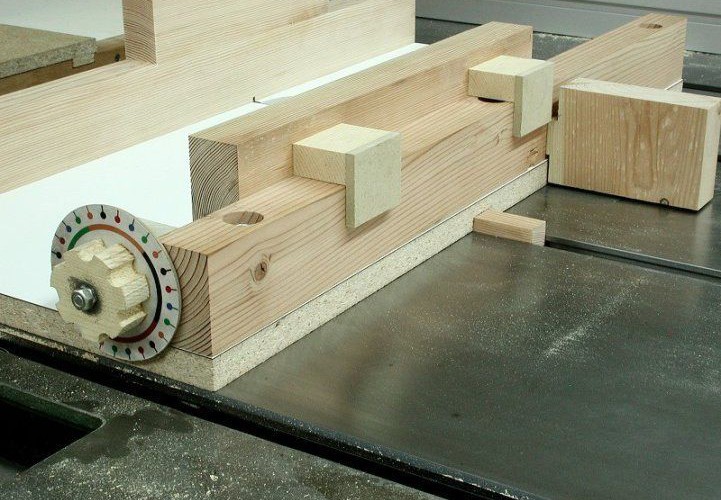

If you fit a stepmotor to an already existing box joint jig, it is necessary to fit a flexible joint between the step motor and spindle. The joint cannot be rigid because even the smallest line error leads to extreme forces/ vibration. A picture is shown below:

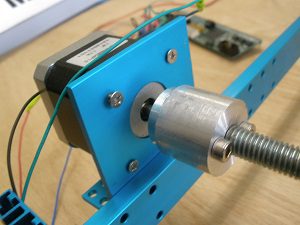

Below you can see a picture where the step motor coupling is fixed. Not the way to go. Your stepmotor bearing will experience axial force and break down.

Your existing sawing jig is probably not optimized for minimum friction. Thus you probably need a bigger step motor to drive the jig than the one we use to drive the jointmaster box joint jig. This is no problem because jointmaster kit A/B can drive any step motor driver. The step motor driver is shown in the picture below (component in the middle)

Note that when you add more step motor power to your box joint jig it also becomes more dangerous for your fingers. You might have to take additional measures to prevent your fingers entering dangerous areas.

A step motor is sized using the NEMA XX notation where XX is for example 17 meaning the stepmotor is 1.7 inch wide. The step motor length can vary. The step motor we use is a NEMA 17 54 mm long with 90 N-cm holding torque.

A Nema size 34 (can be bought all over the internet) with a length of 60 mm will do probably do on all existing box joint jigs. Holding torque will then be around 290 N-cm. To reach the 290 N-cm the phase current is higher. 6.3 Ampere. Thus you also need a heavier step motor driver. The step motor driver we use in the Jointmaster box joint jig can handle at maximum 4.5 Ampere.

Also your power supply has to be heavier because the power supply we advertise can deliver at maximum 3 Ampere.

Why do we advertise sound based step motor control ?

- It is the most simple way to interface a step motor because you need only a few extra components.

- You can easily test if the signal exists on the interface because you can listen to the sound(Try the free version to listen).

If you need 3 or 4 axis control, take a look at Linux CNC based milling.

Far more important, you can also relax, buy art, or take your prescripted mental joint